Factory Tour: Ernie Ball Music Man Part 1

The story of Ernie Ball Music Man is a complex and interesting one that is steeped in authentic guitar builder’s history. The company has had some of the true geniuses in the guitar building world playing key roles, starting in the 1970s with Leo Fender, Tom Walker, and Sterling Ball. This innovative and original company has produced some legendary instruments since then, including the famous Stingray bass, the Axis guitars, and continues to push the envelope with their current focus on new models and innovative electronic technology like the Game Changer pickup switching system. After Ernie Ball took over Music Man in the 1980s, a factory was built in beautiful San Luis Obispo, California, where the all the guitars and basses are built today to a very high standard that is rooted in the original guitar building tradition born decades before.

Join us as we take a look inside this factory and go start to finish with the Music Men (and Music Women) who create these amazing instruments. Thanks so much to everyone at Ernie Ball Music Man who were such great hosts and helped to make this tour happen.

So what does it take to build a legendary amazing Ernie Ball Music Man guitars or bass? Join us at their bright, friendly factory in San Luis Obispo, California as we go step by step through the process.

As usual, it all starts with the wood. Music Man primarily uses ash, mahogany, maple, and ebony for its instruments, although sometimes some exotic woods like spalted maple and koa are employed. Ash is a popular choice for the Stingray basses because of the aggressive sound it produces.

These neck blanks are made of flamed maple and are sourced from a premium supplier. Plain wood necks are milled from lumber inside the Music Man factory. Even though the wood arrives already seasoned, all the wood sits acclimating for at least 30 days.

Here are some delicious looking ebony blanks that will become fretboards eventually.

Some of the maple Music Man uses is “roasted”, which gives that dark, caramel color. It takes kiln drying at 600 degrees to achieve the incredibly low moisture content that is the hallmark of this process. The resulting wood is strong, light, and LOUD!

The first and most basic step in building the instrument: gluing bodies together. The factory produces one, two, and three piece bodies for the various models.

Once the bodies are glued together, they’re weighed and the decision as to what model guitar or bass they will become is made.

For the fancy figured tops you’re used to seeing underneath Music Man’s stunning paint jobs, a bookmatched top is essential. Here, two matched pieces of maple are joined in the center.

The rough body shape will be cut out using the plans found on these individual body shape templates.

This builder has used a template to draw the shape of a guitar’s body shape on a body blank, then used this band saw to roughly cut it out. He has also created the locating holes that will be used in the next step: the CNC machine.

On guitars like the Axis and the Steve Morse models, the binding on the edges of the guitar is actually a special epoxy filler. First the CNC machine cuts a channel in a body blank, then a worker fills it with the goo that will harden and become a tough binding once the body is completey revealed from the blank. Pretty cool trick.

Here’s the date and part number stamped in the cavity. The rest of the workers will refer to this unique part number for the rest of the process to know what they’re building. All the guitars at Music Man are built to order based on dealer requests.

Here’s a mix of shaped bodies mingling with the rough cut blanks.

Installing the inserts for the tremolo block in a shaped body.

Pressing in the inserts for the bridge. Making it look easy!

This machine is what’s known as the “time saver”. It’s essentially a conveyor belt system that will sand down a precise thickness of the wood. It would take a lot longer to do this by hand, thus the name.

Here’s a pretty cool process. Music Man will go to the trouble of installing a mahogany tone block inside certain models. It’s an extra step but worth it in the name of tone. Then the figured maple bookmatched tops are applied to the bodies. This machine uses super strong vacuum pressure to literally bend the tops to the shape of the bodies, where they are glued forever.

On to the necks. All the face and side dots are inlayed by hand. The Music Man necks are very likeable. Easy to play, and the finish is famously smooth.

This machine is apparently designed to haunt your nightmares. During the day though, it cuts the slots in the fingerboard for the frets. Keep those hands in your pockets!

While we’ve got our hands in our pockets, let’s have a look at the automatic press that installs the frets into the fretboard.

When you look closely at your guitar or bass, you’ll see that the fingerboard is gently curved from side to side. That’s the fingerboard radius and that’s what is being created with this custom-made swinger arm machine. The builder will move the fingerboard in an arc against the belt sander, and create the exact radius (each guitar model is different) in a single motion.

Applying glue to the body with a paintbrush.

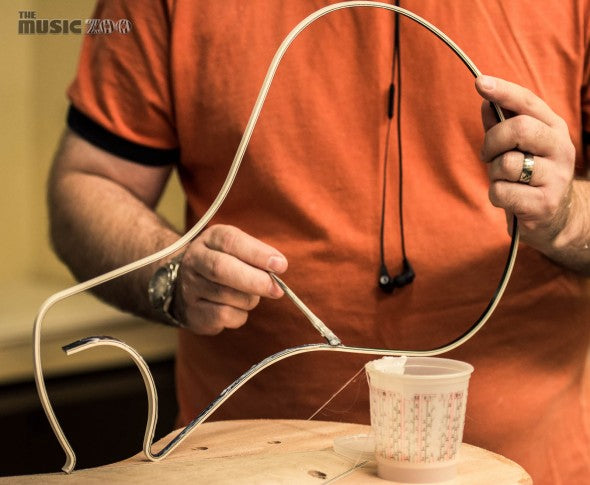

Applying glue to the binding strip. Notice how the binding strip has already been formed to the shape of the body. This will make it easier to seat properly and also reduce the amount of time it needs to be squeezed together.

After the frets are installed in a neck, the fret ends are clipped off. This worker is filling the tiny gaps in the fret ends that may still exist with a Micarta composite. She’ll use the soldering iron to heat the goop and put a tiny amount in each crevice.

These guys are working on the final body sanding station to smooth out any subtle machining marks left by the CNC process.

The final neck sanding station. It takes a lot of training and concentration to correct all the subtle imperfections in the wood every time. These guys are good at what they do.

Click here to see Part 2 of the tour!